Understanding the culture relevance in the analysis, design and evaluation process is the way to ensure that Greencycle bamboo bike is materially, economically and environmentally sustainable. Initial two years research study focused on looking at how to improve the bicycle manufacturing process so that it was cleaner and didn't rely on unsustainable processes, together with exploring the use of renewable materials. Through this study process and time spent in understanding the culture of users in Indonesia, the focus shifted. To understand the creation of the Greencycle, a participatory design approach was applied in the design process that included a series of interviews of the target users, prototype testing and field experiments with sustainable resources, in order to propose, design and evaluate the Greencycle. Designer : Paulus Maringka

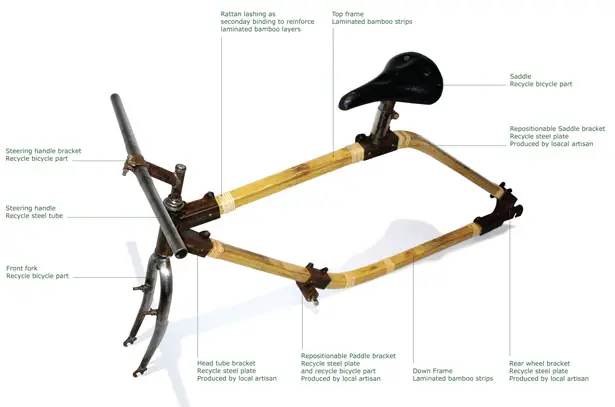

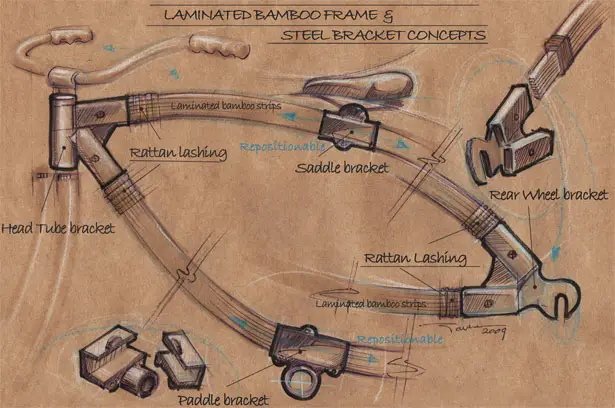

The design process applies system design thinking, informed by cultural insights, to improve on this form of human powered transportation, taking into account the behavior, belief and value relevance, functionality, the needs and wants of the users and the use of appropriate technologies and environmental considerations. A laminating process was used to create the form for the bicycle frame as this is a relatively easy, economical and low technology process. Two identical curved laminated bamboo pieces were placed in opposite directions and joined using simple steel brackets to produce a simple but yet very strong construction. This construction also allows for the seat and paddle bracket to be adjusted along the two curved frames to suit different users. Rattan lashing was also used as a secondary binding to reinforce the laminated bamboo layers.

The production and manufacturing of Greencycle bamboo bike was done in Indonesia to test the skills and capabilities of the local craftsmen. This provided important insights into the local craftsmen's capabilities and limitations which will be used in the ideation process for the next generation of Greencycle design idea. Taking into consideration the limitation of local skills, recycled parts were used in the construction of Greencycle bamboo bike. Exploring local skills and the crafts industry and choosing readily available materials and parts not only helps to create jobs for local industry but keeps costs economical to ensure product sustainability. |

Friday, August 12, 2011

Greencycle Bamboo Bicycle

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment